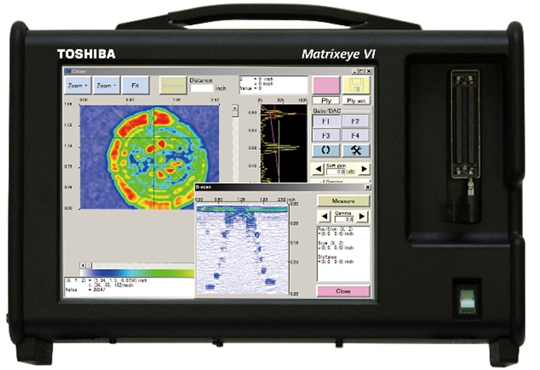

3D SAFT Inspection Equipment Matrixeye™VI with Phased Array Function

Features

General-purpose ultrasonic inspection equipment that pursues "visibility" for a wide variety of products

High-resolution, high-sensitivity ultrasonic inspection system with 3D SAFT-PA (3D aperture synthesis, phase and array) function

- Responding to a variety of inspection needs, including composite materials (e.g.,CFRP) such as aircraft fuselages metal castings, welds, and inspection of railway components.

Increased flaw detection speed

- Enhanced data communication by switching to SSD-based storage,and higher CPU and memory capacity.

- Flaw detection speed: Up to 1.9 times faster than our previous model

Improved environmental resistance

- A closed-loop cooling system improves stable operation in a dust environment

Abundant applications

- Supports not only vertical inspection but also bevel(angled) detection.

- Offline analysis using 3D image data is supported.

- Enables the construction of inspection system by using simple mechanism and encoder input.

Advanced analysis software

- Generate A-, B-, and C-scan images and allows configuration of DACs (Distance Amplitude Correction) and GATEs

- Enables automatic defect area calcutation by applying customized color palettes and threshold values.

Basic specifications

| Item | Description | |

|---|---|---|

| Environmental conditions | Operating temperature range | 5~35°C |

| Relative humidity | 20 to 80% No condensation | |

| General for equipment | Dimensions (W x H x D) | 345 x 230.5 x 125 mm (Including the protruding parts) |

| Weight | Approx. 5.5 kg (with 1 battery pack), Approx. 6.5 kg (with 2) | |

| CPU | Pentium N3710 1.60 GHz | |

| Memory | 4 GB | |

| Storage | SSD 512 GB | |

| OS | Windows10 IoT Enterprise (32 bit) | |

| Display | 10.4-inch LCD panel (XGA) | |

| USB | 2.0 x 2 , 3.0 x 2 | |

| Video output | HDMI | |

| Ethernet | 1000BASE-T | |

| Encoder | TTL logic input (6 bit) | |

| Power supply | Battery type | Li-ion battery (94 Wh) |

| Battery run-time | 3 h (with 1 battery ),6 h (with 2 batteries) | |

| AC | 100〜240 V , 50 / 60Hz | |

| Accessory |

Keyboard, Mouse, Battery x 2, Auxiliary battery case, Battery Charger AC adapter (for Main Unit and for Battery Charger) Power supply cord (for Main Unit and for Battery Charger), Couplant |

|

* The specifications are subject to change without prior notice.

| Items | Specifications | |

|---|---|---|

| Pulsar | Range of transmission delay | 2.5 ns |

| Transmission delay setting range | 0~51.197 μs (2.5μs increments) | |

| Number of simultaneous excitations | 1~64ch | |

| Pulse voltage | 20V~180V | |

| Transmission pulse width | variable (12.5ns~1000ns) 2.5ns/step | |

| Receiver | Number of receive channels | 64ch |

| Amplifier frequency range | 1 M~20 MHz | |

| Averaging | 1, 2, 4, 8, 16, 32, 64, 128 | |

| Gain | 0~80 dB | |

| Filter | Digital filter Allows filtering less than 40 MHz | |

| Sampling frequency | 10, 20, 40, 80 MHz | |

| Number of A/D converter | 8 | |

| Imaging | Image update speed | 37 frames/sec or more |

| Image synthetic process | SAFT | |

| Number of parallel process | 96 | |

| Number of mesh | 320 × 1 × 1024 | |

| Number of layers | 3 | |

| Number of focal lows | 128 | |

* All system and product names mentioned are generally registered trademarks or trademarked by their respective companies.

* These specifications are subject to change without prior notice.

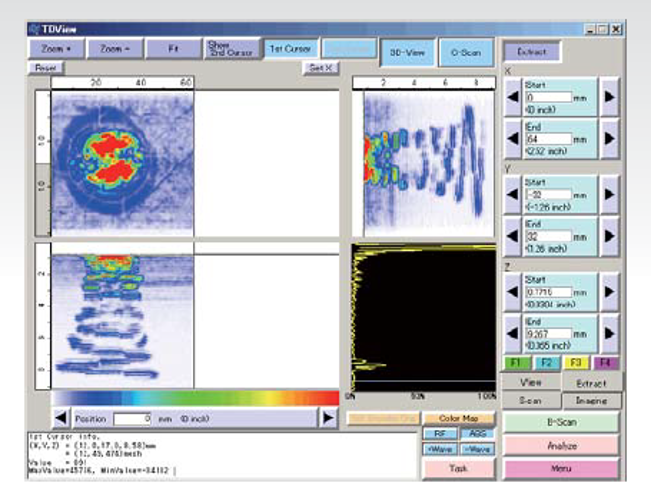

Inspection example

Examples of Images of CFRP Delamination

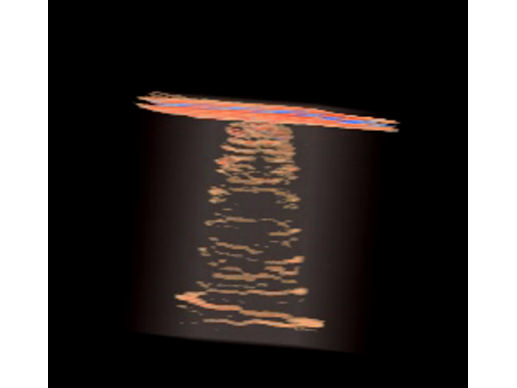

3D Bird's Eye View (optional)

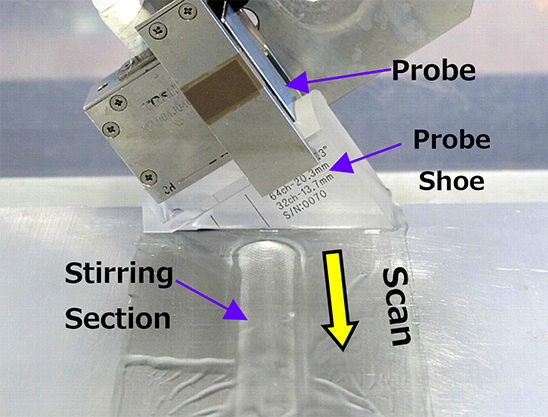

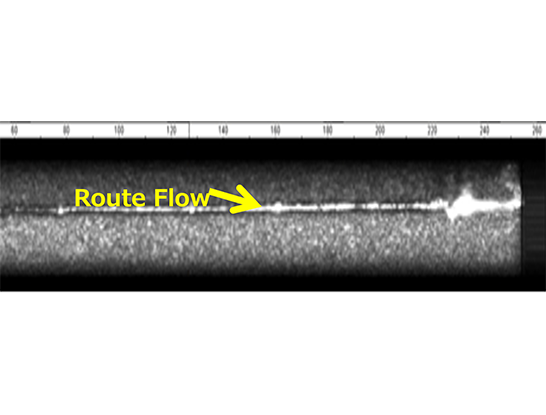

Example of FSW Inspection Results

- Our proprietary P-FMC/TFM(*) technology enable high-resolution imaging of route flow and tunnel defects in friction stir weld FSW diffusion joints.

- Related JIS Z3083 "Ultrasonic flaw detection test method for route flow of friction stirred aluminum and magnesium alloy“.

*: Phased Array Full Matrix Capture/Total Focusing Method

Scanning with Linear Arrays

Example of Flaw Detection Image of Route Flow

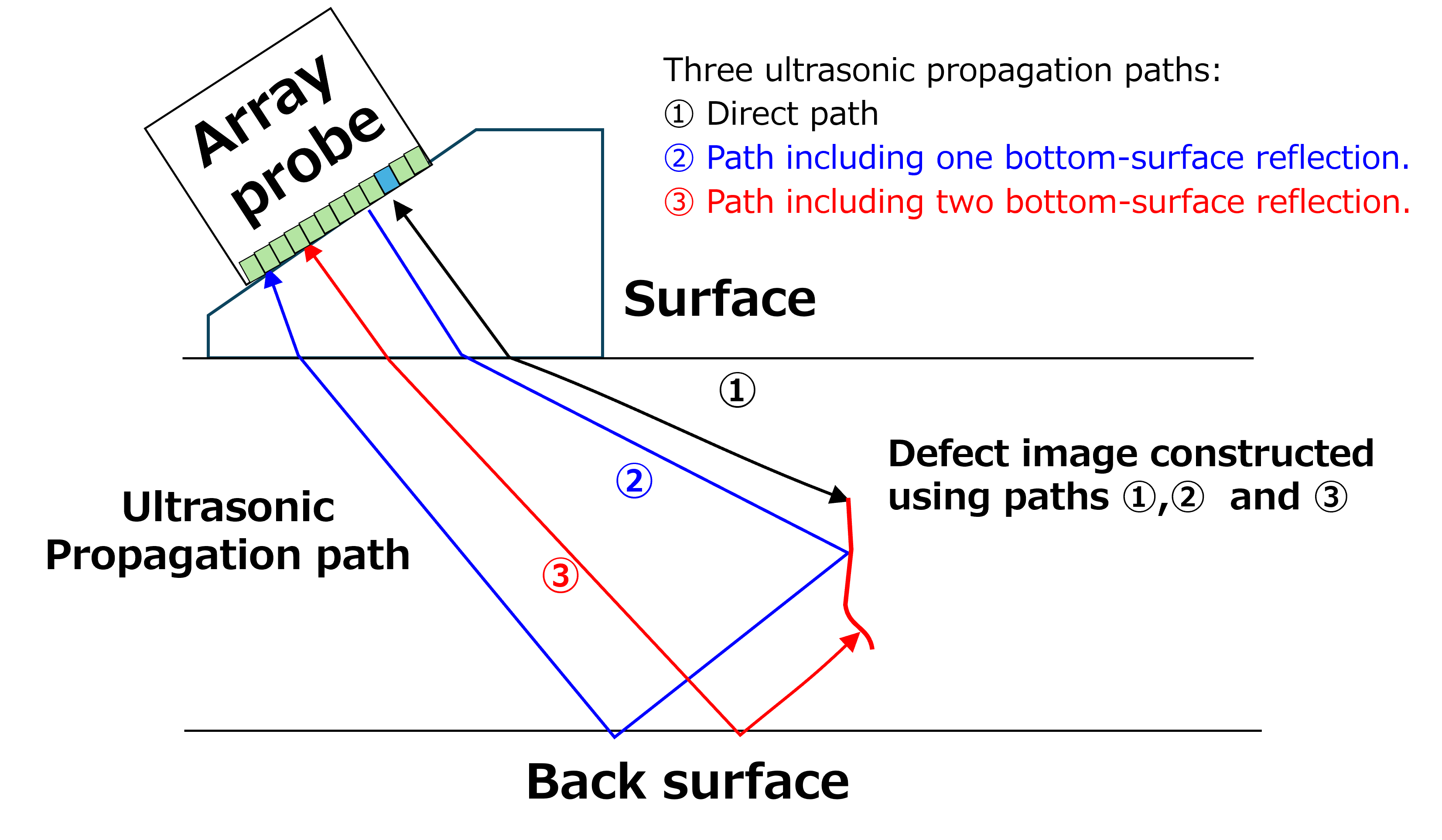

Example of inspection results using MP-FMC/TFM* technology (optional)

Features

- High resolution imaging

- High signal-to-noise ratio (SNR)

- Wide focal area

- Rapid inspection speed

- High transmission strength

- Controllable transmission beam

- Excellent visibility

*: MP-FCM/TFM:Multipath Phased-array Full Matrix Capture/Total Focusing Method

Explanation of Ultrasonic Wave Propagation Paths in MP-FMC/TFM

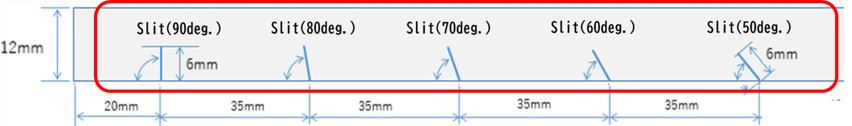

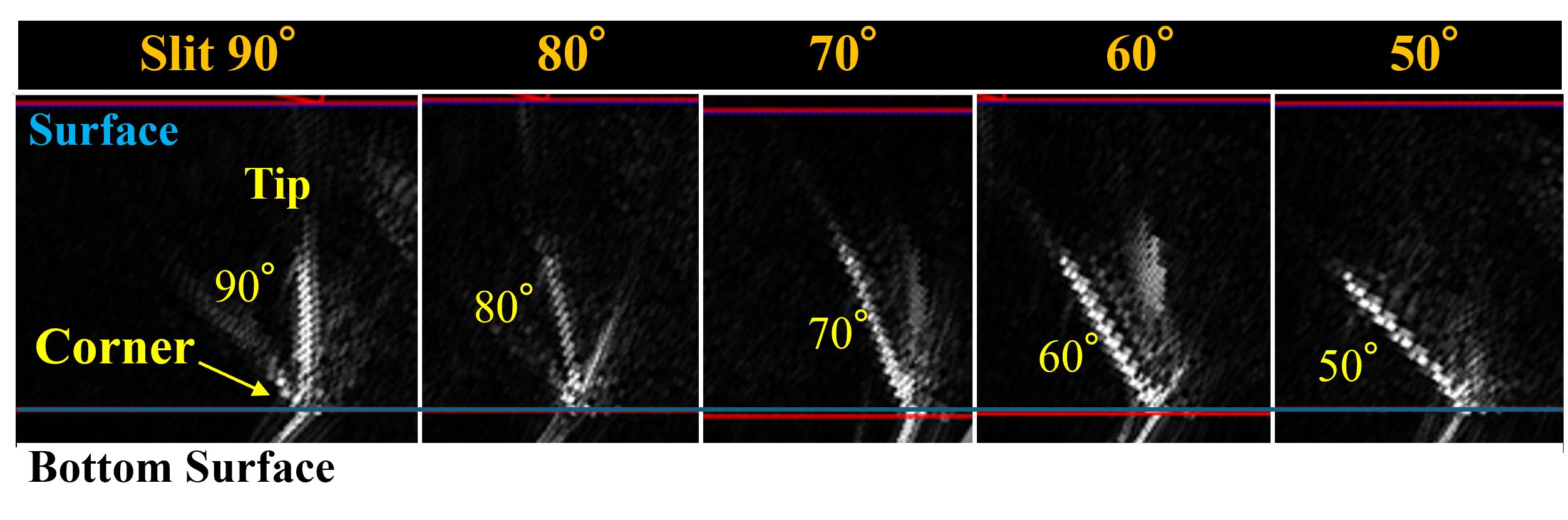

6 mm Length Slits with Different Angles in a 12 mm-Thick Steel Plate

Examples of Inspection Results (Butt Welds)

- Matrixeye™, Finethrough™ are registered trademarks of Toshiba Energy Systems & Solutions Corporation.

- Microsoft, Windows and Excel are registered trademarks of Microsoft Corporation in the United States and other countries.