Matrixeye™ VI+ for Spot Weld Inspection

Features

Ultrasonic inspection system with advanced functions tailored for spot welding inspection

Equipped with 3D SAFT-PA (Three-dimensional Aperture Synthesis and Phased Array)

- Enables highly accurate inspection by detecting hard-to-find blowholes and pressure contact anomalies.

Reduced Inspection Time Through Faster Flaw Detection

- Enhanced CPU performance shorthens display time by approximately 40% compared to our conventional models.

- Image update speed is improved by 1.6 times compared to our conventional model.

Intuitive and Easy-to-Use Interface

- Tilted dent inspection can be performed accurately and efficiently using real-time imaging and tilt guidance function.

- Indication of the next highest inspection position contributes to the reduction of errors in inspection locations, etc.

Easy-to-Read Results Display

- The result database function allows inspection results to be displayed and managed clearly in an easy-to-understand format.

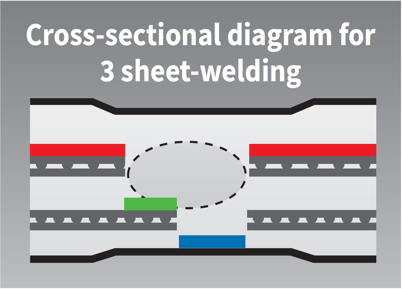

Reliable One-Side Inspection, Even for Multi-Layer Sheets

- Even when inspecting a stack of two or three sheets,the system alows accurate evalution from a single side using automatic flaw detection.

One-handed free inspection is possible with a hand switch. One-Handed Operation with Hand Switch

- The system supports hands-free inspection using a one-handed switch,improving work efficiency and user comfort.

Matrixeye™VI+. Dedicated Spot Weld Inspection Software

Real-time Display of Test Results

Test results are updated in real time during inspection, making it easier to understand and confirm the outcome.

Simple Measurement Mode

This mode enables diameter measurement of the melted area without the need to input thickness data.

Enhanced Pressure Welding

A newly implemented algorithm detects pressure contact conditions and accurately measures actual nuget diameter.

Advanced Automatic Adjustment and Check Functions

In addition to conventional surface adjustment, the software now includes sensitivity adjustment, shoe friction check , and probe check functions-ensuring consistently stable inspection quality.

Improved operability

The user interface has been significantly enhanced previous software,offering clearer categorization and intuitive nagivation for setting parameters and selecting files.

External device

Equipped with for linking to external PLC or PCs,allowing Matrixeye™ to be controlled remotely.

Basic Specifications

| Items | Specifications ※ | Note | |

|---|---|---|---|

| General spec | Dimension | W:345 × D:125 × H:230.5 mm | |

| Weight | Approx. 5.5kg (with 1 battery pack), Approx. 6.5kg (with 2) | ||

| CPU | Intel Atom x6211E | ||

| Memory | 8GB | ||

| Hard disk | SATA SSD 512GB | ||

| OS | Windows10 IoT Enterprise(64bit) | ||

| Display | 10.4-inch touch panel display (XGA) | ||

| USB | 2.0 × 2, 3.0 × 2 | ||

| Video Output | HDMI | ||

| Ethernet | 1000BASE-T | ||

| Encoder | TTL equivalent input: 6 bit | ||

| Power supply | Battery | Li-ion battery (94Wh) | |

| Battery operation time | 3h (with 1 battery), 6h (with 2 batteries) | ||

| AC | 100~240V 50/60Hz | ||

| Ambient Conditions | Ambient temperature | 5~35°C | |

| Ambient humidity | Relative humidity:20-80%, Non condensation |

||

| Imaging | Image compositing process | SAFT | |

| Accessories | Keyboard / Mouse, Battery × 2, Extended battery case Battery charger, AC adapter, Power supply cord (for Main Unit, and for Battery Charger), Couplant |

||

* The specifications above are subject to change without notice.

Basic Functions

| Items | Specifications | Note |

|---|---|---|

| Number of welded plates to be inspected | Two or three plates | If the item you are looking for is not listed, please feel free to contact us. We may still be able to support your request. |

| Collective setting of plate thickness | Minimum thickness: Approx.0.5mm | |

| Maximum total thickness: Approx.6.0mm | ||

| Compatible materials | Steel (including high-tensile steel), Aluminum | |

| Nugget diameter | Approx. 3mm to 8mm | |

| Measurement and judgment items | Joint diameter, joint area, dent depth, weld thickness, pressure | Threshold setting function for n√(t min ) |

* The specifications above are subject to change without notice.

Other features

| Items | Feature |

|---|---|

| Inspection condition creation and management function | It is possible to collectively create and manage multiple RBI points with different inspection parameters for each inspection point as a single program. |

| Surface conditioning function | It recognizes the surface (origin) of the product and automatically adjusts it. By doing it before work, you can minimize daily errors. |

| Coupling check function | It detects the presence or absence of couplant applied between the probe shoe tip and the surface of the part to be inspected and illuminates the lamp if it is insufficient. |

| Parallel support function | This feature allows you to check the parallelism between the nugget surface and the tip of the probe shoe. By equalizing the parallelism, inspection accuracy is improved. |

| Data Management Functions | Data management is easy because the test results can be sorted by items such as pass/fail, test date, inspector, etc. |

* The specifications above are subject to change without notice.

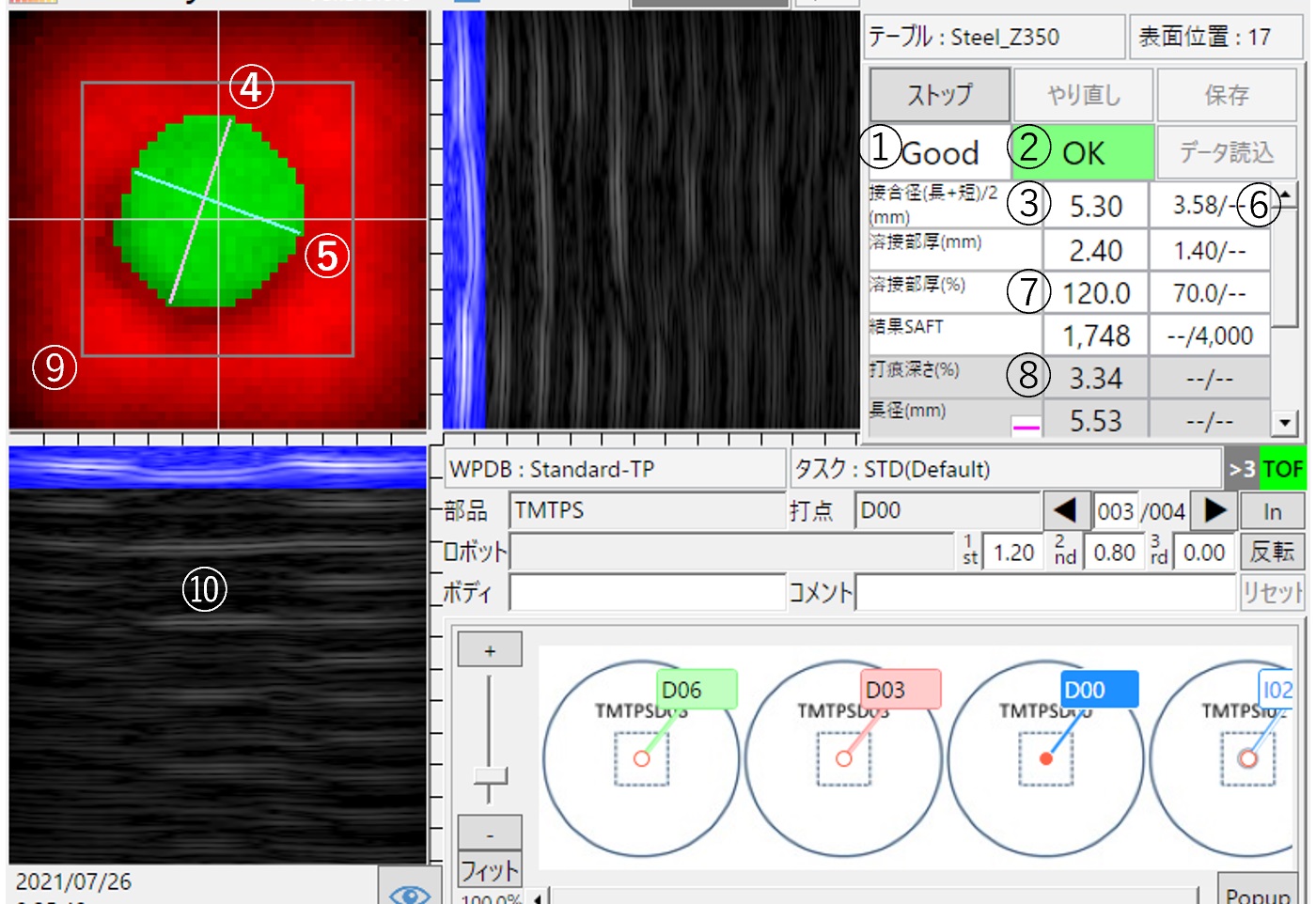

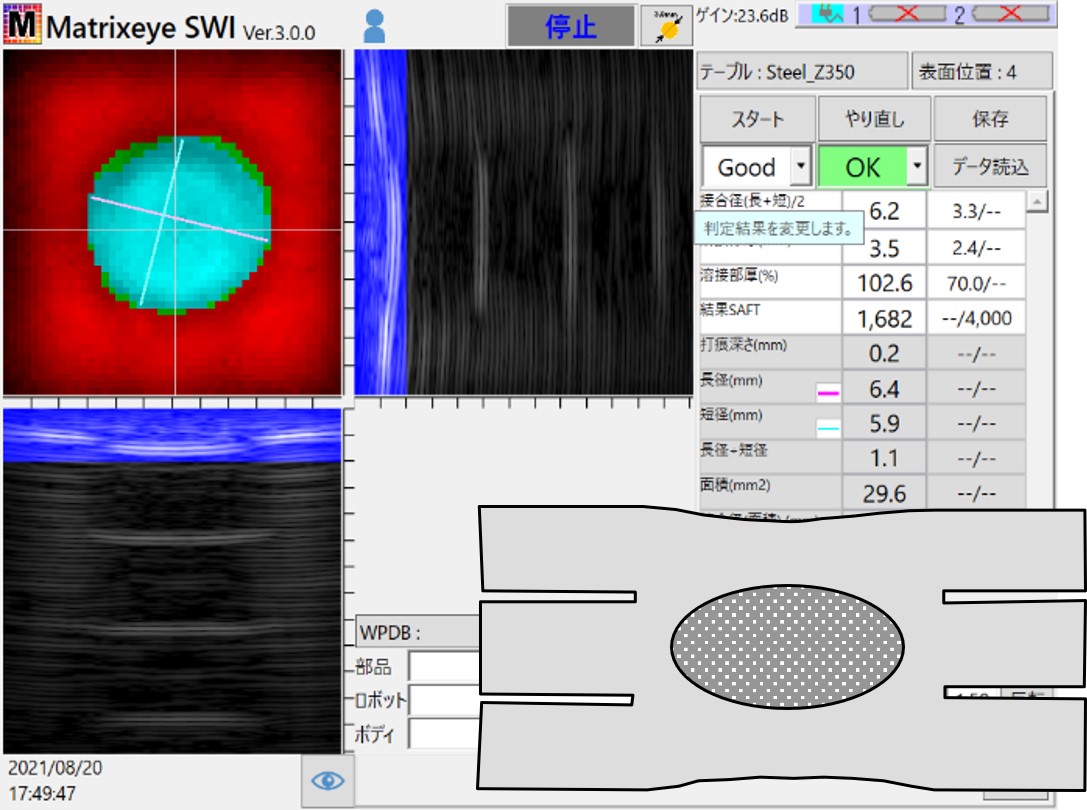

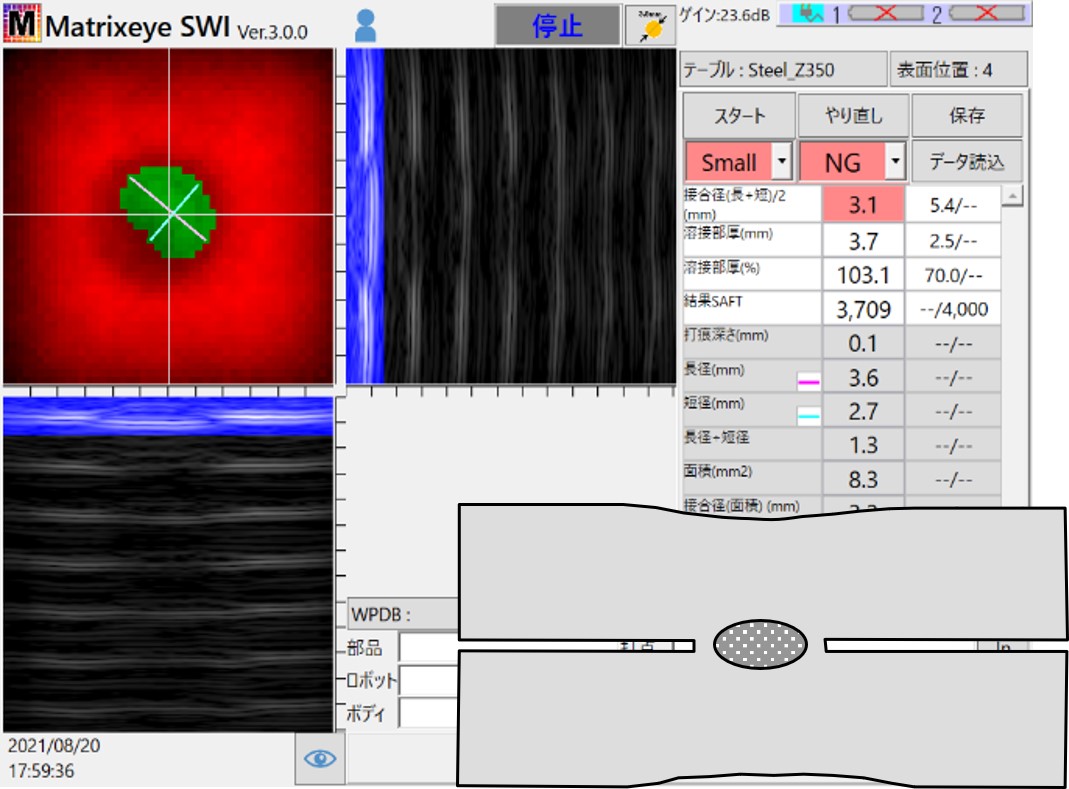

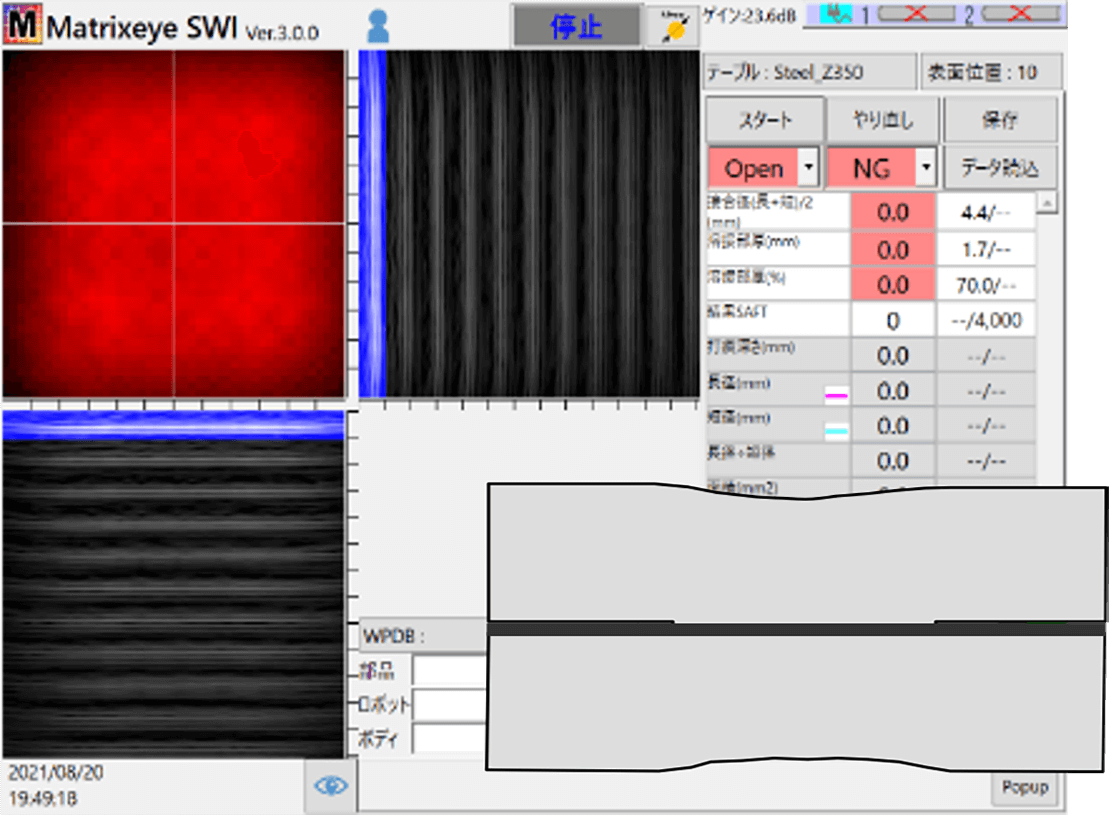

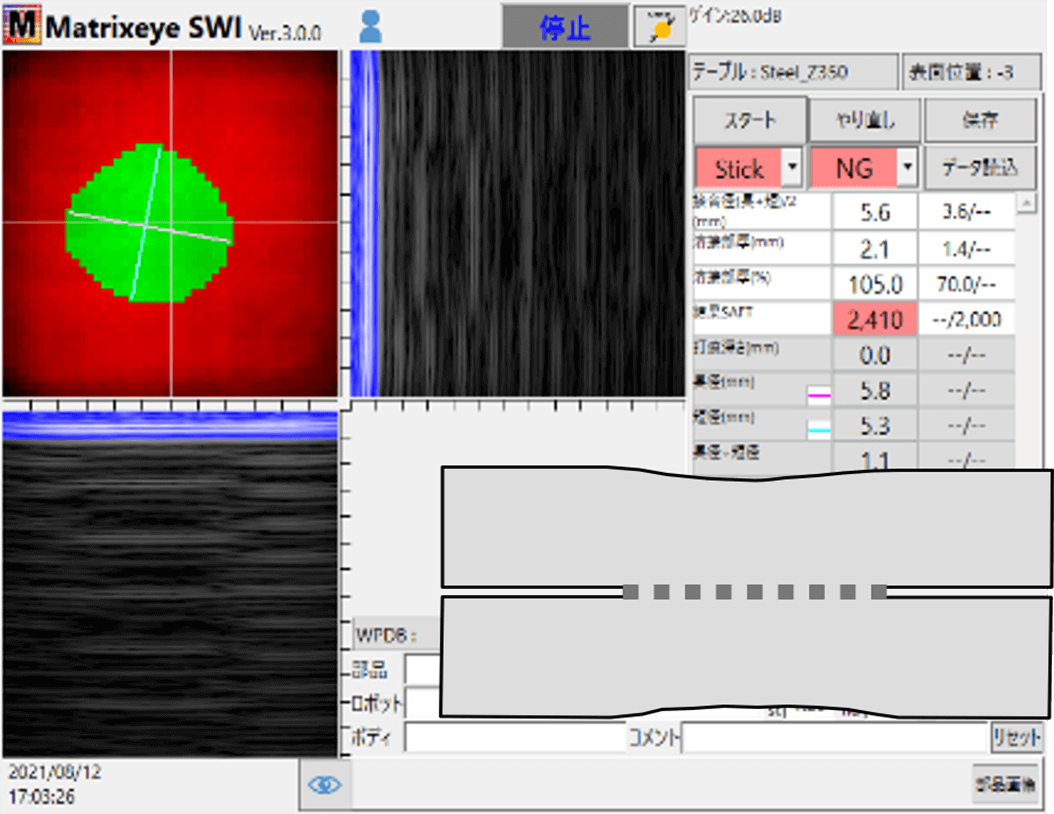

Inspection Example

- ①:Automatic Measurement Result

(Good, Small, Open, Thin, Stick) - ②:Automatic Judgment Result (OK,NG,N.A.)

- ③:Diameter of Joint Area: (④+⑤)/2

- ④:Major Axis of Joint Area

- ⑤ Minor Axis of Joint Area

- ⑥:Threshold of Diameter

- ⑦:Thickness of Joint Area

- ⑧:Depth of Indentation

- ⑨:C-scan Screen

Red area: Bottom surface of the 1st sheet

Green area: Bottom surface of the 2nd sheet

Blue area: Joint area

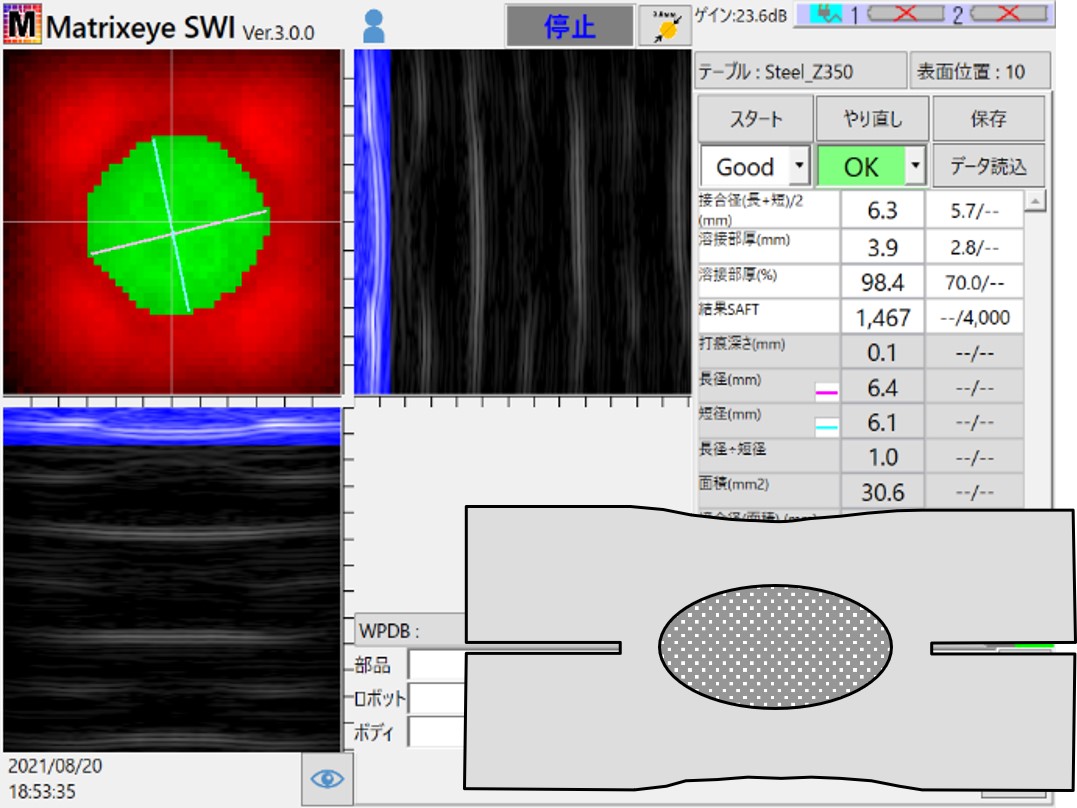

Example of Inspection Results

Good(Two)

Good(Three plates)

small

open

Press welding condition

- Matrixeye™, Finethrough™ are registered trademarks of Toshiba Energy Systems & Solutions Corporation.

- Microsoft, Windows and Excel are registered trademarks of Microsoft Corporation in the United States and other countries.