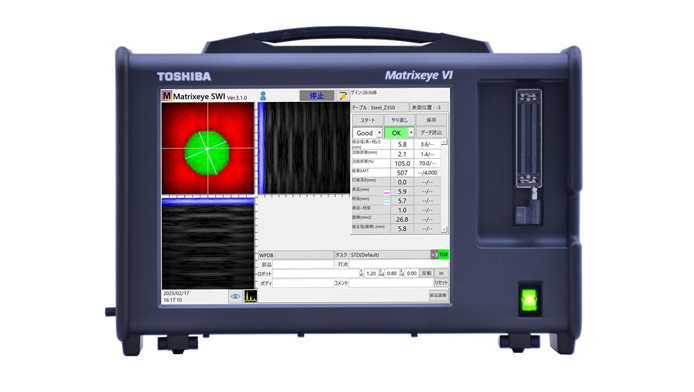

3D Ultrasonic Inspection System (Matrixeye™)

Detailed High-Resolution imaging of Internal Structures and Defect Shapes

We offer advanced 3D ultrasonic flaw detection systems that surpass conventional technologies.Equipped with a transducer containing up 256 piezoelectiric elements arranged in a matrix,the system rapidly acquires thousands to tens of thousands of waveforms.These signals are then processed using image synthesis techiques to generate high-speed,high-resolution 3D images of the internal structure of the object under inspection.